White Cross Back Chairs: The Ultimate Guide to Materials, Craftsmanship, And Market Selection

The White Cross Back Chair has long been an icon in the event rental, hospitality, and residential interior design industries.

Its distinctive “X” back design—inspired by traditional French bistro aesthetics—perfectly balances rustic charm with modern elegance.

However, for B2B buyers, distributors, and event planners, the challenge lies in choosing the right material.

Whether it is for high-end wedding rentals or high-traffic restaurant environments, the choice between Resin, Wood, and Metal dictates not only the aesthetic appeal but also the longevity, maintenance, and ROI of the investment.

In this comprehensive guide, we delve into the technical nuances of each material, their production processes, and strategic styling tips involving cushions and dining tables.

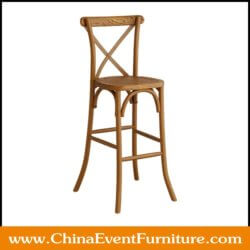

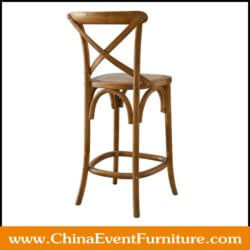

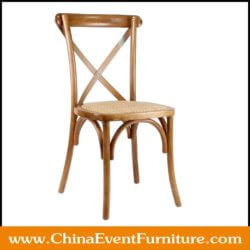

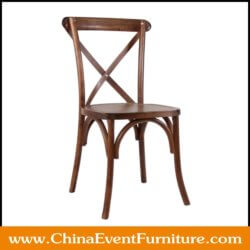

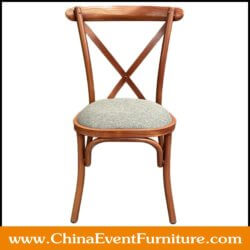

1. Solid Wood White Cross Back Chairs: The Timeless Classic

Wooden cross back chairs are the “gold standard” for authenticity. They provide a warmth and texture that synthetic materials simply cannot replicate.

Production Process & Structural Integrity

The manufacturing of a high-quality wood cross back chair typically involves Solid Beechwood or Oak.

- Steam Bending Technology: The iconic “X” and the curved backrest are achieved through precision steam bending. This process involves heating the wood fibers until they are pliable, then shaping them in specialized molds.

- This ensures the grain remains continuous, significantly increasing the strength compared to cut-out pieces.

- Tenon and Mortise Joinery: Premium models utilize traditional joinery reinforced with metal bolts in high-stress areas. The “bentwood” ring under the seat provides lateral stability, ensuring the chair can withstand weight capacities exceeding 250kg.

Surface Treatment: The Art of “White”

Achieving a durable white finish on wood requires a multi-stage process:

- Sanding: High-grit mechanical sanding to ensure a smooth base.

- Priming: Application of an anti-tannin primer to prevent wood oils from bleeding through and yellowing the white paint.

- Lacquer Coating: Multiple layers of NC (Nitrocellulose) or PU (Polyurethane) paint. For a “Vintage White” look, craftsmen often apply a manual distressing technique followed by a clear protective topcoat.

Best Use Case

Ideal for indoor high-end weddings and permanent restaurant seating where the tactile feel of wood adds to the brand’s prestige.

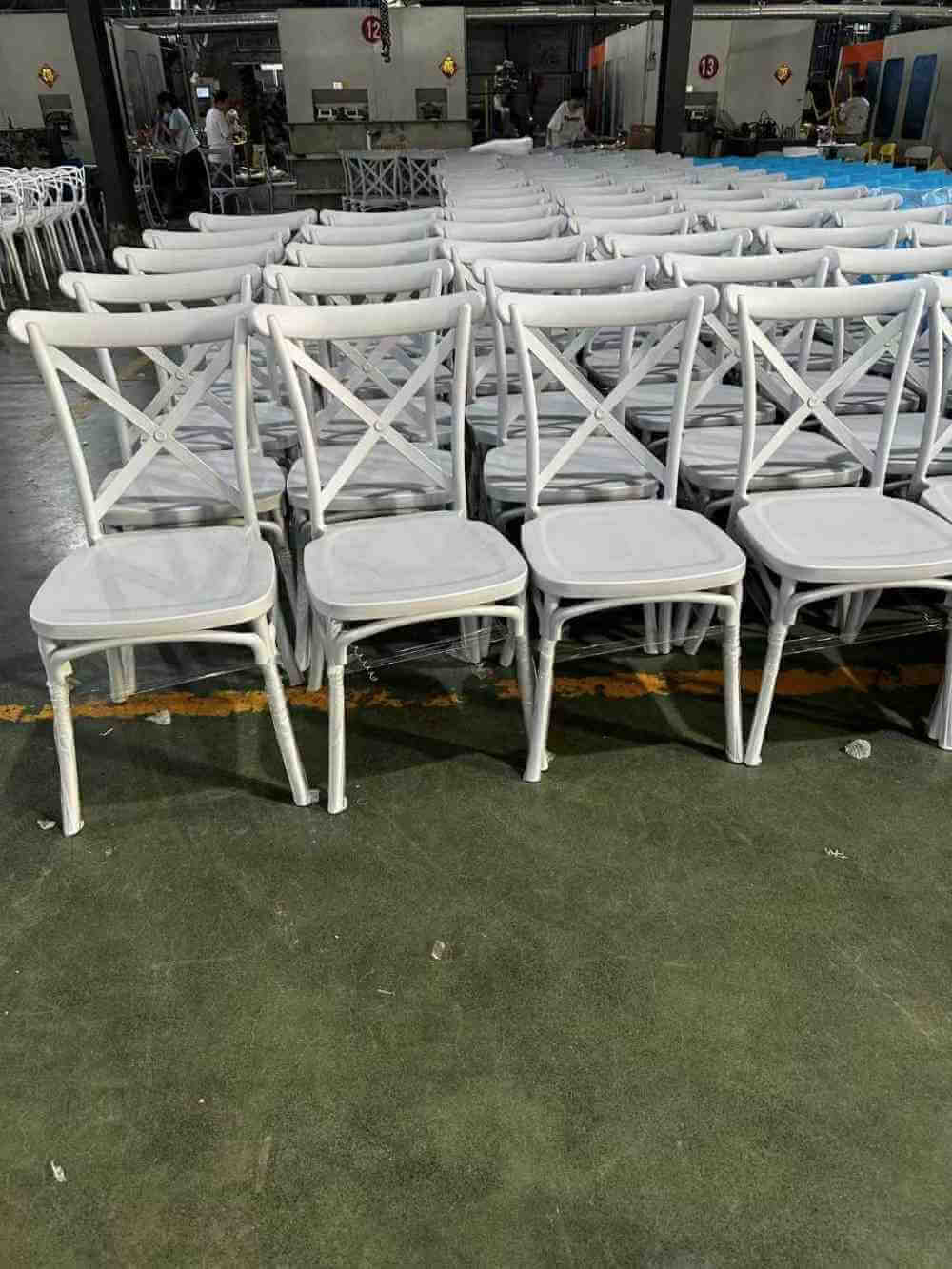

2. Resin (Polypropylene) White Cross Back Chairs: The King of Durability

For high-frequency event rentals, Resin (PP) is often the preferred choice due to its weather resistance and ease of maintenance.

Production Process: Gas-Assisted Injection Molding

Unlike wood, resin chairs are produced via high-pressure injection molding.

- One-Piece Construction: Most modern resin cross back chairs are molded in a single piece. This eliminates joints—the weakest point of any chair—making them virtually indestructible.

- Gas-Injection Technology: Nitrogen gas is injected into the mold to create a hollow internal structure in the legs and frame. This reduces weight without compromising the structural rigidity, making them easier for staff to stack and transport.

Material Characteristics & UV Protection

The “White” in resin chairs isn’t painted; it is pigmented throughout the material.

- UV Inhibitors: Quality manufacturers mix UV-stabilizers into the resin pellets. This prevents the white color from turning brittle or yellowing under direct sunlight, a critical factor for outdoor garden ceremonies.

- Anti-Static Finish: The surface is treated to repel dust and facilitate quick cleaning with a simple damp cloth.

Best Use Case

Outdoor events, coastal venues, and rental companies require a lightweight, stackable, and waterproof solution.

3. Metal (Steel or Aluminum) White Cross Back Chairs: Industrial Strength

Metal cross back chairs offer a unique “Industrial Chic” vibe and are practically immune to the warping issues sometimes seen in wood.

Engineering & Construction

- Welding Techniques: These chairs are constructed using heavy-duty steel or lightweight aluminum tubing. Full-seam CO2 welding is used at all connection points to ensure the frame does not wobble over time.

- Reinforced Seat Pan: Often features a metal plate or reinforced cross-bars under the seat to prevent sagging.

Surface Treatment: Powder Coating

The white finish on metal chairs is achieved through Electrostatic Powder Coating:

- Pre-treatment: The metal is acid-washed to remove impurities.

- Powder Application: Dry white powder is electrostatically applied to the frame.

- Curing: The chair is baked in an oven at high temperatures, melting the powder into a hard, scratch-resistant “skin” that is far more durable than liquid paint.

Best Use Case

Bistro patios, high-traffic cafes, and modern farmhouse-style dining rooms.

4. Maximizing Comfort: The Role of Cushions

While the design of the cross back chair is ergonomic, adding a cushion is essential for long-duration seating comfort.

- Tie-on Cushions: Perfect for the rustic look of wood chairs. Usually made of high-density foam wrapped in linen or burlap fabric.

- Hard-Board Cushions: These feature a wooden base covered in foam and fabric, often with “Velcro” or “Elastic Tie” systems to secure them to the seat.

- Color Synergy: While the chair is white, a charcoal grey or navy blue seat cushion can create a sophisticated contrast, while a cream or white cushion enhances the “all-white” minimalist aesthetic.

5. Styling with Tables: Creating a Cohesive Space

The White Cross Back Chair is incredibly versatile when paired with different dining tables:

- The Farmhouse Look: Pair white wood cross back chairs with a Solid Oak Farmhouse Table. The contrast between the crisp white finish and the natural wood grain creates a warm, inviting atmosphere.

- Modern Minimalist: Match resin white chairs with a Glossy White Lacquer Table or a glass-top table for a clean, seamless look.

- The Industrial Mix: Use metal white chairs with a Reclaimed Wood Table featuring black iron legs to lean into the popular “Modern Industrial” trend.

6. Comparison Summary: Which One to Choose?

| Feature | Wood | Resin (PP) | Metal (Steel/Aluminum) |

|---|---|---|---|

| Aesthetic | Authentic, Classic | Sleek, Modern | Industrial, Edgy |

| Weight | Moderate | Lightweight | Heavy (Steel) / Light (Alu) |

| Durability | High (Indoor) | Ultra-High (All-weather) | High (Scratch-resistant) |

| Maintenance | Requires care | Low (Wipe clean) | Low |

| Stackability | Limited | Excellent | Excellent |

Conclusion

Investing in White Cross Back Chairs requires a deep understanding of your target environment.

If you prioritize tradition and tactile quality, Wood is your winner. If your business model revolves around logistics, outdoor versatility, and longevity, Resin is the smartest investment.

For those seeking an indestructible, modern-industrial look, Metal stands unrivaled.

To complete your event setup, don’t forget to explore our latest collection of event cushions and heavy-duty banquet tables to ensure your guests enjoy both style and comfort.

For more information on bulk orders or customized finishing options, please contact our technical sales team.