The Definitive Guide to Chiavari Counter Stools: Materials, Ergonomics, and Global Procurement

Executive Summary

The Chiavari chair, originally conceived in 1807 in the coastal town of Chiavari, Italy, has transcended its historical roots to become a global symbol of elegance and prestige.

As modern commercial design shifts toward multifunctional spaces—blending high-traffic hospitality with luxury aesthetics—the Chiavari Counter Stool has emerged as a critical asset.

This whitepaper provides an exhaustive analysis of the Chiavari stool, focusing on the technical nuances of material selection (Solid Wood vs. Metal vs. Resin), ergonomic standards, and strategic procurement for high-ROI business operations.

I. Material Science: The Triple Pillar of Commercial Durability

In the high-stakes world of hospitality and event rentals, material choice is not merely an aesthetic preference; it is a financial strategy.

The Chiavari silhouette may be consistent, but the “DNA” of the stool determines its lifespan, maintenance costs, and market positioning.

1. Solid Wood Chiavari Counter Stool: The Artisan Standard

The most traditional choice is typically crafted from European Beechwood or Rubberwood.

- The Structural Advantage: Wood possesses natural elasticity. When a guest shifts weight on a 30-inch stool, the wood fiber absorbs micro-vibrations better than rigid alternatives.

- High-quality wooden stools utilize deep mortise-and-tenon joinery, reinforced with industrial-grade adhesives and internal steel screws.

- Aesthetic Superiority: For luxury wedding venues and high-end residential islands, the tactile warmth of wood is irreplaceable.

- Our finishing process involves a multi-stage hand-sanding followed by 7 layers of premium lacquer, ensuring a deep, rich “Mahogany” or “Champagne Gold” luster.

- Restoration ROI: Wood is the only material that is truly “repairable.” Scratches and nicks—inevitable in commercial use—can be treated with touch-up pens or light refinishing, extending the product life cycle to 8-10 years.

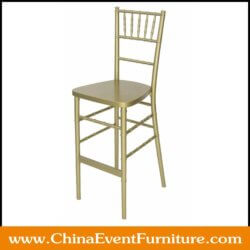

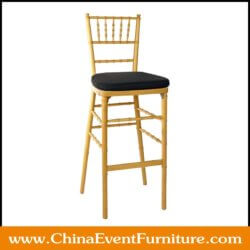

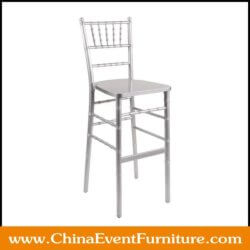

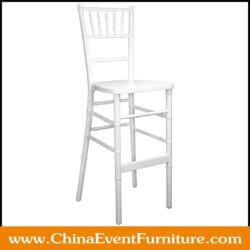

2. High-Grade Aluminum Chiavari Counter Stool: The Efficiency Engine

Engineered for the rigorous demands of the event rental industry and outdoor hospitality.

- Weatherproofing & Oxidation Resistance: Aluminum stools are naturally rust-proof, making them the gold standard for rooftop bars, poolside lounges, and coastal resorts.

- The Weight-to-Strength Ratio: An aluminum Chiavari stool is approximately 30-40% lighter than its wooden counterpart while maintaining a static load capacity of over 1,000 lbs.

- This drastically reduces labor costs during setup and minimizes shipping fees for international logistics.

- Seamless Finish: Modern powder-coating techniques allow aluminum to mimic the look of wood or polished chrome, offering a sleek, “commercial-chic” aesthetic that requires zero maintenance.

3. Resin & Polycarbonate Chiavari Counter Stool: The Modern Illusion

Often referred to as the “Ice Chair” or “Ghost Stool,” resin Chiavari stools represent the peak of 21st-century furniture engineering.

- Monoblock Technology: These stools are manufactured using high-pressure injection molding.

- Because they are a single solid piece (or “K/D” with reinforced joints), there are no screws to loosen over time. This eliminates the “wobble” that plagues inferior stools.

- Visual Transparency: In compact urban bars or crowded cocktail hours, the transparent resin allows light to pass through, preventing the space from feeling cluttered.

- It creates a “magical” atmosphere, particularly under professional event lighting.

- Color Permanence: Unlike painted stools, the color in a resin stool is infused throughout the material. If the surface is scratched, the color remains consistent, making it virtually immune to “chipping.”

II. Technical Specifications & Ergonomic Engineering

Procuring the wrong height is the most common and costly mistake in commercial design. We categorize stools into two distinct industrial tiers:

1. The “Counter” Height Standard

- Seat Height: 24 – 26 inches (60 – 66 cm).

- Target Surface: Designed for 36-inch (91 cm) surfaces.

- Application: Ideal for kitchen islands, breakfast nooks, and hotel lobby “workstations.” It promotes a casual, seated-eye-level interaction.

2. The “Bar” Height Standard

- Seat Height: 30 inches (76 cm).

- Target Surface: Designed for 42-inch (107 cm) surfaces.

- Application: High-intensity commercial bars, wedding cocktail tables, and gala high-tops. This height is engineered for “perching,” allowing guests to transition easily between standing and sitting.

3. Structural Reinforcement (The “Four-Rung” Rule)

Because stools have a higher center of gravity than chairs, lateral stability is paramount. Premium Chiavari stools must feature:

- Reinforced Stretchers: Horizontal bars connecting the legs must be placed at varying heights to distribute stress.

- Kick Plate Integration: A stainless steel or brass “kick plate” on the front rung protects the finish from the friction of shoes, a detail that separates “retail” stools from “commercial-grade” assets.

III. Competitive Analysis Matrix

| Metric | Solid Beechwood | Pro-Aluminum | Virgin Resin (K-Resin) |

|---|---|---|---|

| Durability Rating | High (Indoor) | Ultra-High (All-Weather) | High (Structural) |

| Weight per Stool | 5.5 kg – 6.5 kg | 3.8 kg – 4.5 kg | 5.0 kg |

| Stacking Capability | 2-4 Stools High | 5-8 Stools High | 5-10 Stools High |

| Maintenance Need | Periodic tightening | Low | Low (Cleaning only) |

| Ideal Environment | Ballrooms, Private Clubs | Beach Clubs, Rentals | Art Galleries, Nightclubs |

IV. Strategic Procurement: Global Sourcing & Quality Control

For B2B buyers (Wholesalers, Importers, Designers), the following “Red Flags” should be monitored during the factory audit process:

- Recycled vs. Virgin Materials: Ensure that resin stools are made from 100% Virgin Polycarbonate. Recycled plastics are brittle and will yellow or crack under UV exposure.

- Paint Curing: For metal and wood, check for “Baking Paint” processes. A finish that hasn’t been properly cured will flake off within months of commercial use.

- The “Wobble Test”: Every stool should be tested on a precision-leveled surface. Even a 2mm discrepancy in leg length indicates poor quality control in the assembly jig.

V. Design Trends: The Evolution of the “Chiavari Aesthetic”

While the classic “Gold Chiavari” remains a bestseller, the market is diversifying:

- Distressed “Antique” Finishes: Popular in “Rustic-Industrial” bar designs.

- Monochromatic “Velvet” Cushions: Moving away from standard vinyl to high-performance polyester velvets that are stain-resistant but offer a softer touch.

- The “Naked” Stool: A trend toward using the stool without a cushion, highlighting the intricate bamboo-style carving of the resin or wood frame.

VI. Conclusion: Maximizing Your Investment

The Chiavari Counter Stool is a rare furniture piece that serves as both a functional seat and a decorative element.

For a rental business, the Aluminum or Resin versions offer the fastest return on investment due to their durability and low maintenance.

For interior designers focusing on high-end hospitality, the Solid Wood version offers the unmatched “Old World” luxury that discerning clients demand.

By understanding the synergy between material science and ergonomic standards, you can procure assets that do not just fill a room but elevate the entire brand experience of a venue.