The Engineering, Aesthetics, And ROI of White Wood Chiavari Chairs

Executive Summary

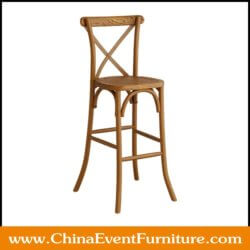

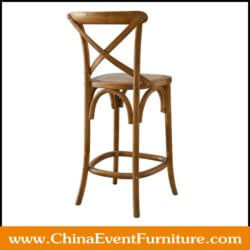

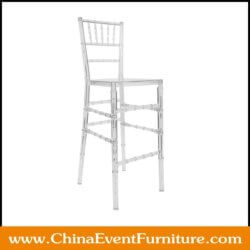

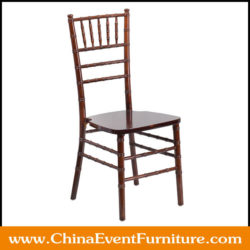

For over two centuries, the Chiavari Chair has remained the gold standard of event seating. However, the White Wood Chiavari Chair represents a unique intersection of classical Italian design and modern minimalist luxury.

This industry white paper explores the structural integrity, multi-layer coating technology, and economic advantages of solid wood construction over synthetic alternatives, providing event professionals and rental moguls with the data needed for high-stakes procurement.

I. Architectural Heritage and Modern Market Demand

Originating in 1807 in the town of Chiavari, Italy, the chair’s iconic spindle-back design was engineered to be “light but incredibly strong.”

In today’s SEO landscape, queries for “White Wood Chiavari Chairs” are inextricably linked with high-end weddings, diplomatic galas, and luxury corporate branding.

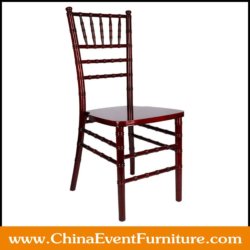

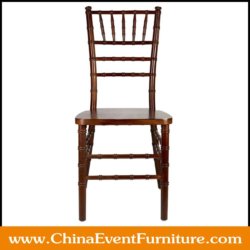

While resin and metal imitations exist, the solid wood variant remains the premier choice due to its organic warmth, acoustic dampening properties, and the superior way it reflects professional stage lighting without the “plastic glare” of synthetic materials.

II. Material Science: The Superiority of European Beech and Locust Wood

The longevity of a white-finished chair depends entirely on the biological stability of the timber used.

1. Species Selection and Kiln-Drying

We utilize premium European Beechwood and Locust Wood, selected for their high density and tight grain structure.

- Moisture Content Control: All timber undergoes a rigorous kiln-drying process to reach a stabilized moisture level of 8% to 12%. This prevents the wood from shrinking or expanding—the primary cause of paint cracking in inferior white chairs.

- Impact Resistance: High-density hardwoods absorb the shocks of frequent transport and high-traffic usage better than hollow metal or brittle resins.

2. Structural Reinforcement (The “Pro-Grade” Build)

To withstand the rigors of the global rental industry, our chairs feature:

- Quadrilateral Support Rungs: Four reinforced rungs connecting the legs to distribute weight evenly.

- Hidden Steel Brackets: Every seat-to-leg joint is reinforced with heavy-duty internal steel brackets, ensuring a static load capacity exceeding 1,000 lbs (450 kg).

III. The Seven-Layer Coating System: Achieving the Perfect “Snow White”

The most significant challenge for white furniture is “yellowing” and “chipping.” Our proprietary Seven-Layer Coating System solves these industry pain points.

1. Primer Sealing (Anti-Tannin Barrier)

We apply two layers of high-grade sealing primer. This creates a chemical barrier that prevents wood tannins and oils from seeping through, which typically causes unsightly yellow spots on cheaper white chairs.

2. UV-Resistant Lacquer (The Finish)

Our topcoats are formulated with UV-inhibitors.

- Color Retention: Even under direct sunlight during outdoor garden weddings, the finish maintains a crisp, “Cool White” hue rather than fading into a “Vintage Cream.”

- Hardness Rating: The lacquer achieves a 2H hardness rating, providing a scratch-resistant surface that survives the stacking and unstacking process.

IV. Economic Analysis: Return on Investment (ROI) for Rental Businesses

Procuring white wood Chiavari chairs is a strategic asset investment. Here is how they outperform alternatives:

| Feature | Solid Wood (White) | Resin/Plastic | Metal/Aluminum |

|---|---|---|---|

| Repairability | High (Sanding/Repainting) | None (Brittle) | Low (Dents) |

| Acoustics | Soft, muffled sound | Hollow, loud clatter | Sharp, metallic ringing |

| Resale Value | 60-70% after 5 years | 20-30% (Scratches) | 40-50% |

| Sustainability | Biodegradable/Natural | Petroleum-based | Energy-intensive |

1. Repairability = Longevity

Unlike resin chairs, which must be discarded once scratched, wood chairs can be easily refurbished. A simple touch-up kit or a full professional respray can restore a 10-year-old wood chair to “like-new” condition, effectively doubling the asset’s lifespan.

2. Premium Rental Rates

Market data shows that luxury clients are willing to pay a 15-20% premium for real wood chairs. The tactile feel of wood and its “solid” sound when a guest sits down contribute to a perceived value that justifies higher event pricing.

V. Maintenance and Asset Care Protocols

To maximize the lifespan of your inventory, we recommend the following professional standards:

- Protective Stacking: Use soft chair covers between every unit. Stack no more than 8-10 chairs high to prevent pressure marks.

- Climate Control: Store in a humidity-controlled warehouse to prevent wood expansion.

- Cleaning: Use a damp microfiber cloth with PH-neutral soap. Avoid ammonia-based cleaners, which can degrade the UV-lacquer over time.

VI. Why Choose Our Manufacturing Solutions?

As a global leader in banquet furniture manufacturing, we provide:

- Quality Assurance: 24-point inspection process from raw timber to final export.

- Customization: Available in “Pure White,” “Off-White,” or “Pearl White” finishes with custom upholstery options.

- Global Logistics: Optimized container loading to maximize space and reduce shipping costs per unit.

VII. Frequently Asked Questions (FAQ)

Q: Are white wood Chiavari chairs suitable for outdoor use? A: Yes. While they are designed for durability, we recommend using them for outdoor events and storing them indoors overnight to prevent moisture absorption.

Q: Do these chairs pass BIFMA safety standards? A: Absolutely. Our chairs are tested under BIFMA (Business and Institutional Furniture Manufacturers Association) protocols for both drop-weight and cyclic-load durability.

Q: What is the lead time for a wholesale order? A: We maintain a constant stock of 5,000+ units for immediate shipping, while custom large-scale orders typically have a 25-35 day production window.

Q: Besides wood Chiavari chairs, do you have other items on hot sale? A: Sure, the seat cushions are perfect for your chairs. Also, we have kinds of tables for your events and weddings.